In the water treatment process, flocculants are a very important substance that can promote the aggregation of suspended particulate matter, greatly aiding in their sedimentation and removal. However, in practical applications, the viscosity of the flocculant can change, which in turn can greatly affect the effect of water treatment. High viscosity can cause uneven distribution of the flocculant in the aqueous solution, which has a certain impact on the formation of flocs; on the contrary, if the viscosity decreases, it indicates that the flocculation effect is weakened or the performance has deteriorated. This article starts from the water treatment process, analyzes the main factors that cause the viscosity of flocculants to decrease during the water treatment process, and lays the foundation for the improvement of water treatment processes and the enhancement of treatment effects in the future.

The Importance of Flocculant

Viscosity The relationship between viscosity and flocculation effect Viscosity is an important factor affecting the flocculation effect. After being added to the water, the flocculant must be rapidly and uniformly dispersed to react with the suspended microparticles. When the viscosity of the flocculant is appropriate, it can disperse in the water and fully contact the suspended microparticles, which is conducive to aggregation. Conversely, if the viscosity of the flocculant is too high, it is not easy to disperse uniformly, thereby affecting the flocculation effect; but if the viscosity is too low, it will cause the flocculant to settle too quickly, the diffusion range is too wide, thereby shortening the duration of the reaction and reducing the contact area.

The impact of viscosity on floc formation

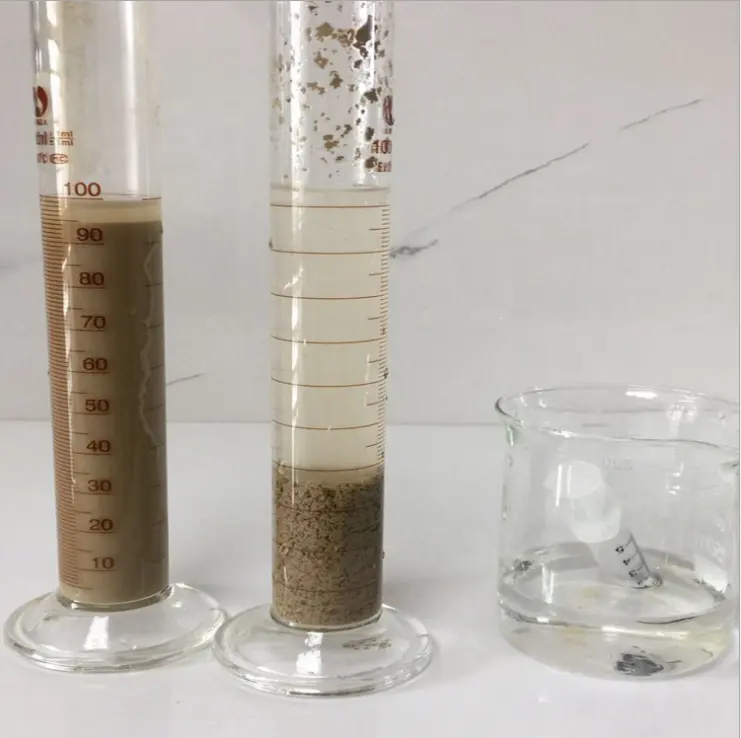

In the water treatment process, the formation of flocs is an important step in removing suspended particulate matter from the water. The appropriate viscosity is conducive to the formation of large flocs between the flocculant and the suspended particulate matter, and the flocs are more compact and stable. The size and stability of the flocculant are the keys to determining its migration and transformation process in the water body, as well as the key factors determining its interaction with other particulates.

The impact of viscosity on settling speed

After flocculation, the flocs produced need to be removed by sedimentation. The settling rate of the flocs is determined by the size, density, and morphology of the flocs, while the viscosity of the flocs will affect the settling rate of the flocs. Theoretically, the larger and more dense flocs are more likely to enter the bottom of the sewage treatment system, and the appropriate viscosity of the flocculant can help form such flocs. If the viscosity is not appropriate, small and light flocs will be produced, with a slow sedimentation rate, thereby affecting the water treatment effect and also requiring additional separation steps.

The reasons for the decrease in the viscosity of water treatment flocculants

Storage time

As the storage time increases, the degree of degradation of the flocculant during storage will decrease, and the flocculation effect will also decrease. Under normal circumstances, the shelf life of anionic PAM solution is 7 days, and that of cationic is 24 hours. This is mainly because the amine is hydrolyzed, causing the number of hydroxyl groups to increase. Among them, the amine reacts with NH3 to form acylamine, which increases the rigidity of the molecular chain, making the effect of the amine more significant.

Mechanical effects

Stirring can increase the dissolution rate of dry powder PAM flocculants, but if the stirring rate is too fast, the molecular chain of PAM will be sheared off. Therefore, it is recommended to control the stirring rate at about 60 rpm to avoid using strong stirring devices and high-speed transmission devices. In addition, due to the aging of the equipment and improper maintenance, such as the wear of the stirring head, etc., the flocculant cannot be fully mixed and reacted.

Temperature effects

At 80-90℃, 18 million molecular weight PAM degrades to about 5 million within 2-4 hours and accelerates with the increase of temperature. At an environment of 25℃, its properties are stable.

Light effects

The temperature rise caused by light exposure causes PAM to dissolve and decompose in the water, while under the action of ultraviolet light, it will be quickly decomposed.

The impact of impurities

Using neutral water to dissolve PAM powder, if the water itself is hard or contains impurities, it will affect the viscosity and application of the water treatment flocculant.

In summary, due to chemical degradation, physical dilution, inappropriate storage conditions, and changes in raw materials, the viscosity of the flocculant is reduced. Recognizing these influencing factors not only can guide the selection and storage of flocculants but also can make appropriate adjustments according to actual conditions