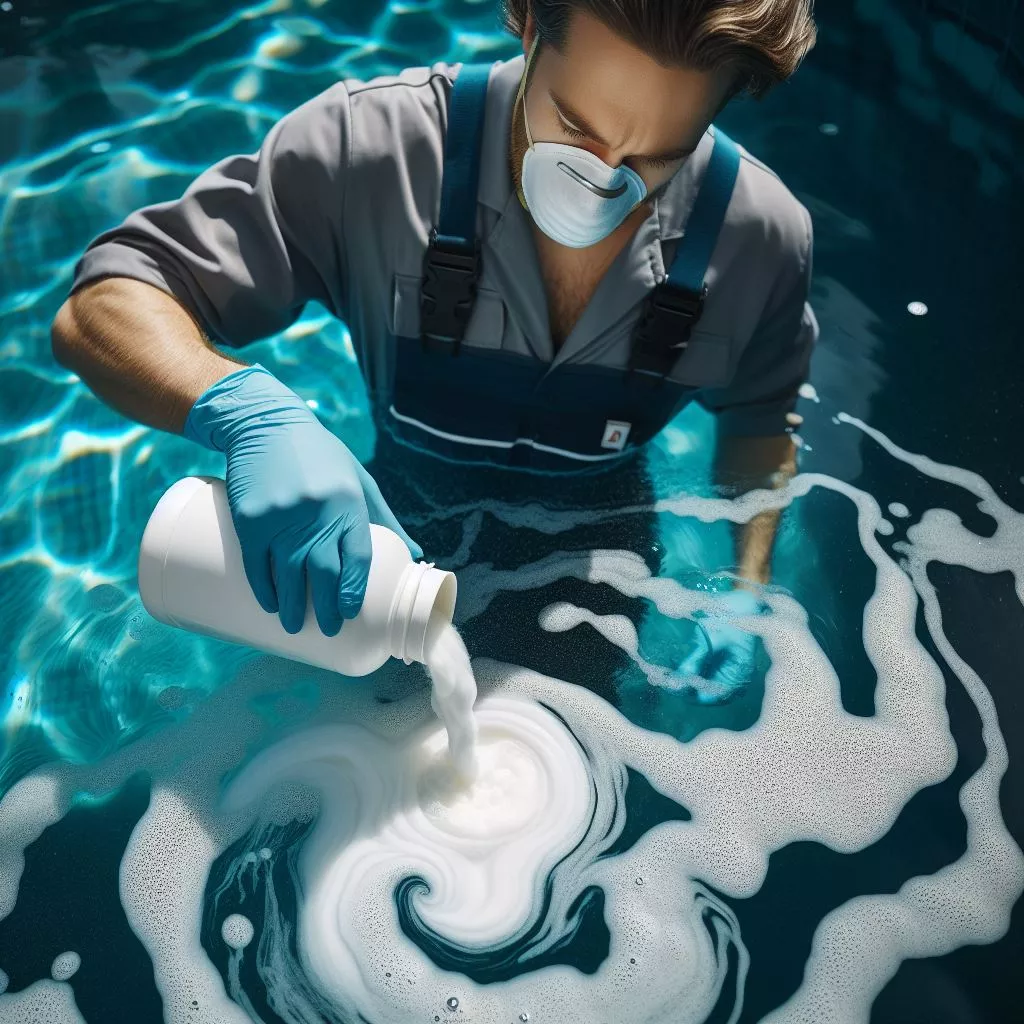

The production of pool flocculants is a meticulous process that involves the creation of specialized chemicals to clarify and enhance the quality of pool water. This article provides an in-depth exploration of the pool flocculant production process, shedding light on the key steps, raw materials, and quality control measures involved in crafting these essential water treatment agents.

Understanding Pool Flocculants

Before delving into the production process, it’s crucial to understand the role of pool flocculants. Flocculants are chemicals designed to aggregate and settle suspended particles in pool water, improving water clarity by facilitating their removal through filtration. The production of pool flocculants aims to create effective agents that optimize the pool water treatment process.

Selection of Raw Materials

The first step in pool flocculant production involves the careful selection of raw materials. Common ingredients include polymers, typically in the form of polyacrylamides or similar compounds. These polymers possess unique properties that enable them to bind with particles in the water, forming larger aggregates that can be easily removed through filtration.

Polymerization Process

The selected polymers undergo a polymerization process, where monomers are chemically bonded together to form long chains. This polymerization is a critical step that determines the characteristics of the final flocculant product. The choice of polymerization method, whether it be solution, emulsion, or suspension polymerization, impacts the flocculant’s efficacy and application in pool water treatment.

Molecular Weight Adjustment

Controlling the molecular weight of the polymer chains is a crucial aspect of the production process. The molecular weight influences the flocculant’s ability to form effective flocs with suspended particles. Manufacturers carefully adjust the molecular weight to achieve the desired balance between rapid flocculation and ease of filtration.

Addition of Functional Groups

To enhance the flocculant’s performance, functional groups may be added to the polymer chains. These groups can improve the flocculation process by providing specific sites for interaction with particles in the water. The addition of functional groups is a tailored approach to fine-tune the flocculant’s capabilities for optimal pool water treatment.

Quality Control and Testing

Quality control is paramount in pool flocculant production. Rigorous testing is conducted throughout the manufacturing process to ensure the consistency and effectiveness of the final product. Parameters such as viscosity, solubility, and flocculation efficiency are meticulously evaluated to meet industry standards and ensure that the flocculant will perform as intended in diverse pool environments.

Formulation Adjustments

Based on the results of quality control testing, formulation adjustments may be made to optimize the flocculant’s performance. Manufacturers may fine-tune the concentrations of polymers, additives, and functional groups to achieve the desired balance of flocculation speed, particle binding, and compatibility with existing pool water treatment systems.

Production Scale-Up

Once the optimal formulation is determined, the production is scaled up to meet market demand. Large-scale reactors and production facilities are employed to produce batches of pool flocculants efficiently. Continuous monitoring and quality assurance measures are maintained to ensure that each batch meets the established specifications.

Packaging and Distribution

The final step in the pool flocculant production process involves packaging and distribution. The produced flocculants are carefully packaged in various forms, including powder or liquid, depending on the application. Proper labeling and instructions are included to guide pool owners on the correct usage and dosage of the flocculant for their specific pool size and conditions.

Environmental Considerations

In line with growing environmental awareness, many manufacturers incorporate eco-friendly practices in pool flocculant production. This includes minimizing waste, utilizing sustainable raw materials, and optimizing production processes to reduce environmental impact. Environmentally conscious production aligns with broader efforts to promote sustainability in the water treatment industry.

Conclusion

The production of pool flocculants is a sophisticated process that combines chemistry, engineering, and quality control to create effective water treatment solutions. From the careful selection of raw materials to the precise adjustment of molecular weights and the formulation of functional groups, each step contributes to the creation of flocculants that optimize pool water clarity. Manufacturers play a crucial role in ensuring that pool flocculants meet stringent quality standards, providing pool owners with reliable and efficient tools for maintaining crystal-clear water in their swimming pools.