Water treatment is a crucial process to ensure the supply of water for drinking, irrigation, recreation, and other purposes, playing a significant role in safeguarding public health and water resource security. This process eliminates pollution, bacteria, and impurities to ensure water quality meets the required standards. During this process, coagulants are added to agglomerate particles and debris, enhancing water quality. Selecting the appropriate coagulant, while fully considering the type of coagulant, its molecular weight, and the properties of the water, is of great importance for improving water quality, reducing sludge volume, and lowering costs. The following text will introduce how to use coagulants and the points to be noted when choosing them.

The Working Process of Flocculation

Ⅰ.Coagulation Process

Coagulation is the primary step in the coagulation process, involving the addition of coagulants and rapid stirring.

Adding Coagulants

Coagulants are chemical substances, such as aluminum sulfate, ferric chloride, etc., which can neutralize the surface charge of particles and accelerate particle agglomeration.

Rapid Stirring

After adding the coagulant, it needs to be quickly stirred to uniformly disperse the coagulant and to fully react with the suspended particles in the water.

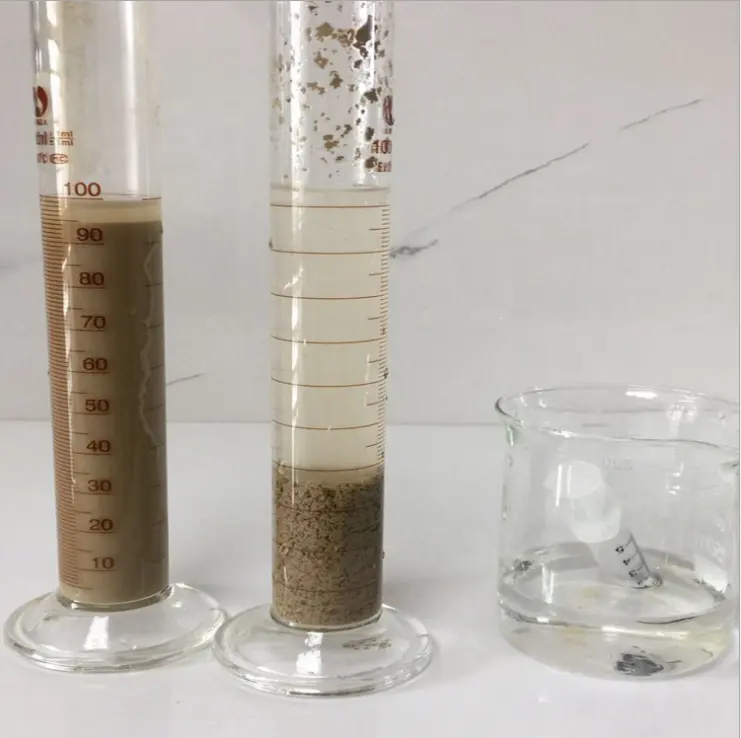

Ⅱ.Flocculation Process

During the coagulation process, the electrostatic repulsion between particles decreases, particles attract each other, and gradually aggregate.

Slow Stirring

Slow stirring can accelerate the formation and growth of flocs.

Floc Growth

During stirring, the flocs continue to grow, and once they reach a certain size, they settle down under their own gravity.

Ⅲ.The Role of Flocculants in Settling and Separating Particles

Increasing Particle Size

Flocculants promote the aggregation of suspended particles, thereby increasing the size of the particles and making them easier to settle under gravity.

Enhancing Sedimentation

Larger flocs settle more slowly, thus improving the effectiveness of the sedimentation zone.

Improving Filtration Efficiency

Flocculation can also be used in filtration, with larger flocs being more easily intercepted by the filter material, thus enhancing filtration efficiency.

Factors to Consider When Choosing Flocculants

PH of the Water Body

The effectiveness of various flocculants varies under different pH conditions. Some flocculants work better in acidic environments, while others are more effective in alkaline conditions.

Properties of Suspended Particles in the Water

Research has been conducted on how the size, shape, density, and surface charge of particles affect flocculation. Understanding the characteristics of suspended particles can provide a basis for choosing the best flocculant.

Water Temperature

Temperature has a certain impact on the flocculation rate; generally, the higher the water temperature, the higher the flocculation rate.

Other Chemicals in the Water

There may be other chemicals in the water that could react with the flocculants, affecting their effectiveness.

Types of Flocculants

Flocculants are mainly divided into two categories: inorganic flocculants and organic flocculants, with different types of flocculants suitable for different situations.

Inorganic Flocculants

Inorganic flocculants mainly refer to metal ions such as aluminum salts and iron salts. These can be hydrolyzed in aqueous solutions to form positive ions, neutralizing the negative charge on the surface of suspended particles and promoting particle aggregation.

Aluminum Salts

Aluminum sulfate: One of the most commonly used inorganic flocculants. After being added to water, it hydrolyzes to form Al³⁺ and SO₄²⁻. Al³⁺ has a strong positive charge, effectively neutralizing the negative charge of suspended particles.

Polyaluminum sulfate: A pre-polymerized form of aluminum sulfate, usually more effective than regular aluminum sulfate, with a lower required dosage.

Iron Salts

Ferrous sulfate: Also a common inorganic flocculant. After being added to water, it hydrolyzes to form Fe²⁺ and SO₄²⁻.

Ferric chloride: In water, it hydrolyzes to form Fe³⁺ and Cl⁻, with Fe³⁺ having a strong positive charge.

Organic Flocculants

Organic flocculants are generally charged organic polymers, categorized by their molecular chain charge characteristics into cationic, anionic, and nonionic types.

Cationic Organic Flocculants

Polyacrylamide (PAM): A common cationic organic flocculant, which can neutralize the negative charge in suspended particles.

Anionic Organic Flocculants

Sodium polyacrylate (PAA-Na): A common anionic organic flocculant, with a molecular chain rich in negative ions, widely used for removing charged particles in water.

Nonionic Organic Flocculants

Polyvinyl alcohol: A nonionic organic polymer flocculant, mainly used in water treatment for some special occasions.

Choosing the appropriate flocculant can effectively remove suspended particles in the water, enhance treatment effects, reduce operational costs, and ensure the water quality meets the required standards. We advise conducting a detailed analysis of the samples and thoroughly understanding some important indicators such as particle properties, pH, temperature, etc., in order to select the most suitable flocculant. As a world-leading chemical product supplier in the industrial field, we have rich experience and can provide various products and personalized solutions for our customers. Please contact us to learn more about how to select the proper flocculant and how we can assist you in improving water quality.